Motor production line

summary:

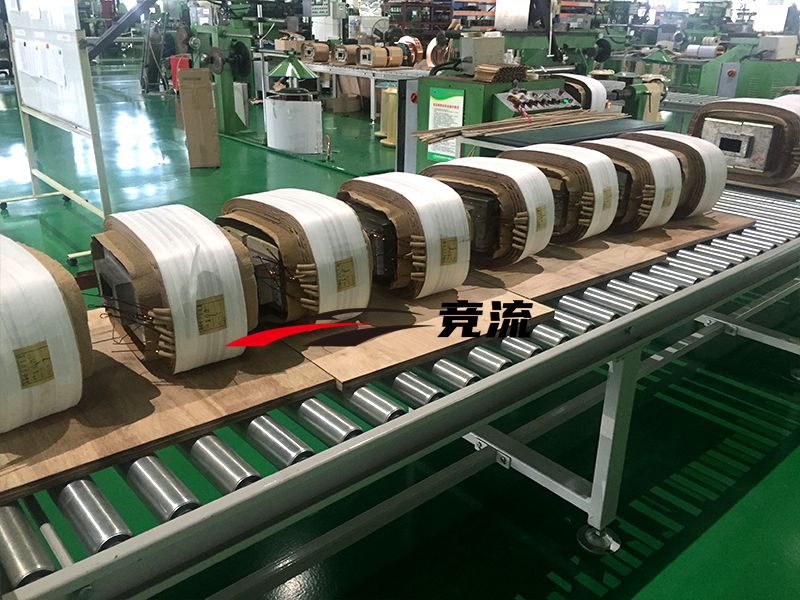

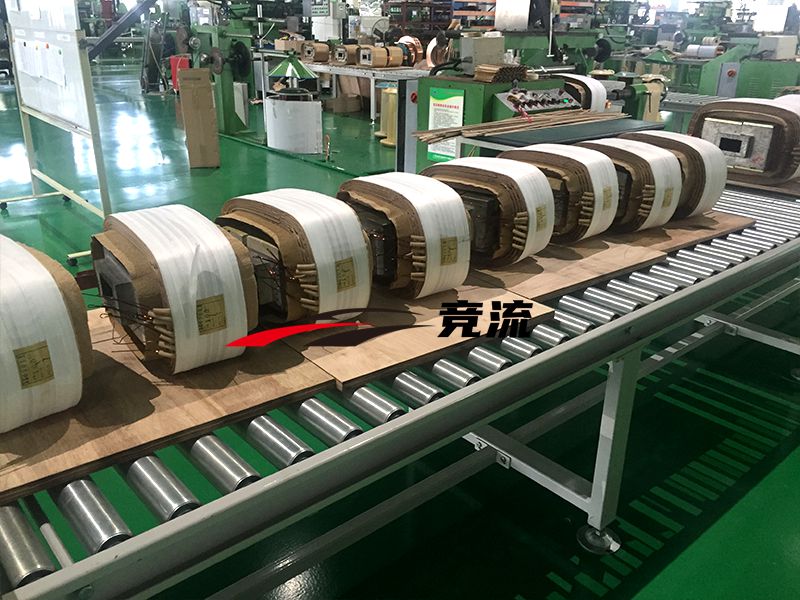

Motors are divided into DC motors, asynchronous motors, and synchronous motors. The motor production line ensures production efficiency and product quality by scientifically planning processes and configuring various automated equipment. Equipment configuration: The motor production line adopts differentiated conveying equipment according to the size of the motor. Small motors are light in weight and small in size, and are often transported by belt lines. The belt line relies on a motor to drive the roller, so that the endless belt generates friction to drive the motor to move. It runs smoothly, has low noise, and the belt is soft and will not scratch the surface of the motor. The large motor has large weight and volume, and adopts a double-speed chain and a roller line for transportation. The double-speed chain uses the speed difference between the chain rollers and the rails to realize asynchronous transportation at different stations, which facilitates the adjustment of the process rhythm; the roller line drives the roller group through the motor, and relies on the carrying capacity of the roller to help large motors improve the efficiency of assembly and inspection. Layout design: The layout design of the motor production line needs to comprehensively consider factors such as production process, material flow, equipment maintenance and personnel operation. Generally adopt a straight or U-shape. The straight type is suitable for simple process scenarios, where materials flow in a single direction, facilitating centralized monitoring; the U-shaped layout shortens the material round-trip path in a limited space, realizing multi-process cyclic operation. In terms of optimizing the layout of the motor production line, processes with similar weights are arranged adjacent to reduce transportation energy consumption; AGV connection ports are set up at key workstations to achieve automatic loading and unloading.

Send Inquiry